Most Reputed Name in PTFE/Non-Stick Coating

A Non-stick Coating has the ability to apply many other properties to the item it is being applied to. Of course non-stick coating’s non-stick properties are probably the most common ones desired, but there are a few other properties, like temperature-related properties, that might be the ones that are actually being sought.

PTFE/Non-Stick Coating

PTFE/Non-Stick Coating

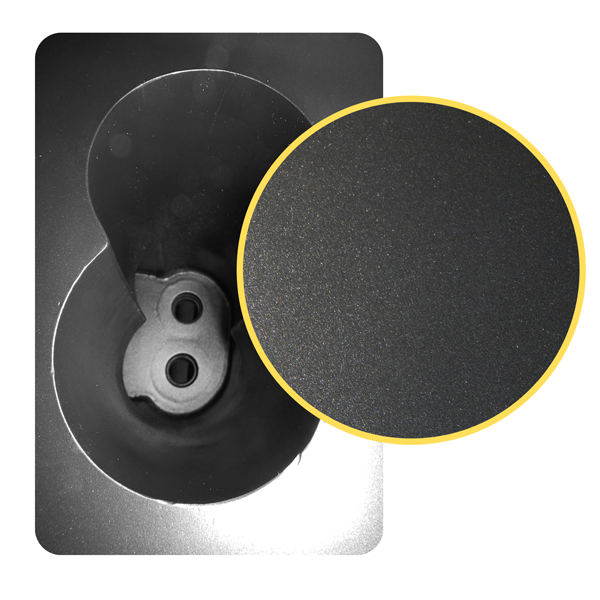

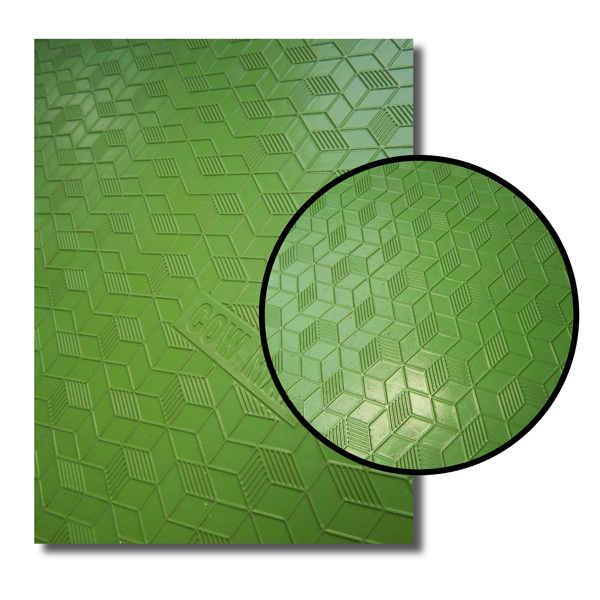

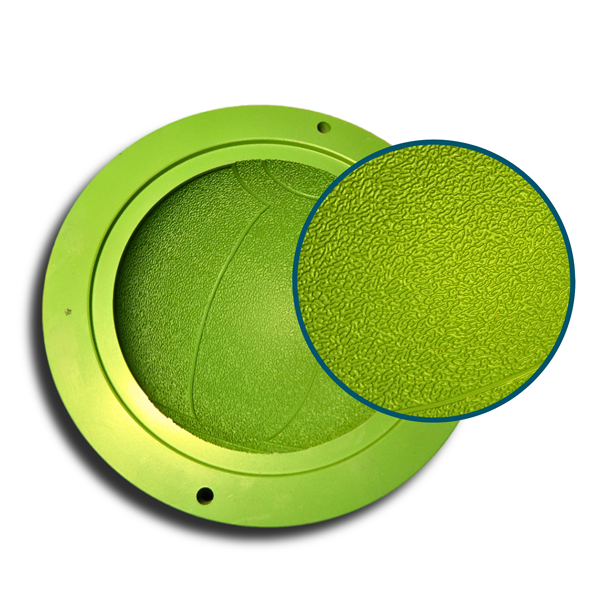

Non-stick Coating also known as anti-rust coating, is done on the surface of the shoe mould. non-stick coating is chemically synthesized from fluoropolymer. This protects the mould’s painted finish and offers a brilliant shine, doing away with the problem of corrosion and wear and tear in high as well as low temperatures, keeping the mould new for a long time. Non-stick Coating protect the moud from getting rust and corrosion. When the drops of non-stick coating dry up, it bonds to the surface, this is the time to start to use another piece of dry cotton to massage it onto the surface and turn it into another transparent layer, shiny coating.

This can be quite laborious as a lot of effort is required; which is why at some centers polishing equipment is used. Once signs of the drops have disappeared, it is wiped once again with a clean cloth to make it free of any residue or dust. The polishing of other plastic parts is done using a typical liquid polish. This brings out the shine in the non-shiny parts and can leave the mould looking better than what it was when it came out of the workshop. Jai Ambay etching process is one of the leading companies in Non-stick Coating and has been a part of the industry since 2008.

A Non-stick Coating has the ability to apply many other properties to the item it is being applied to.

.png)

.png)